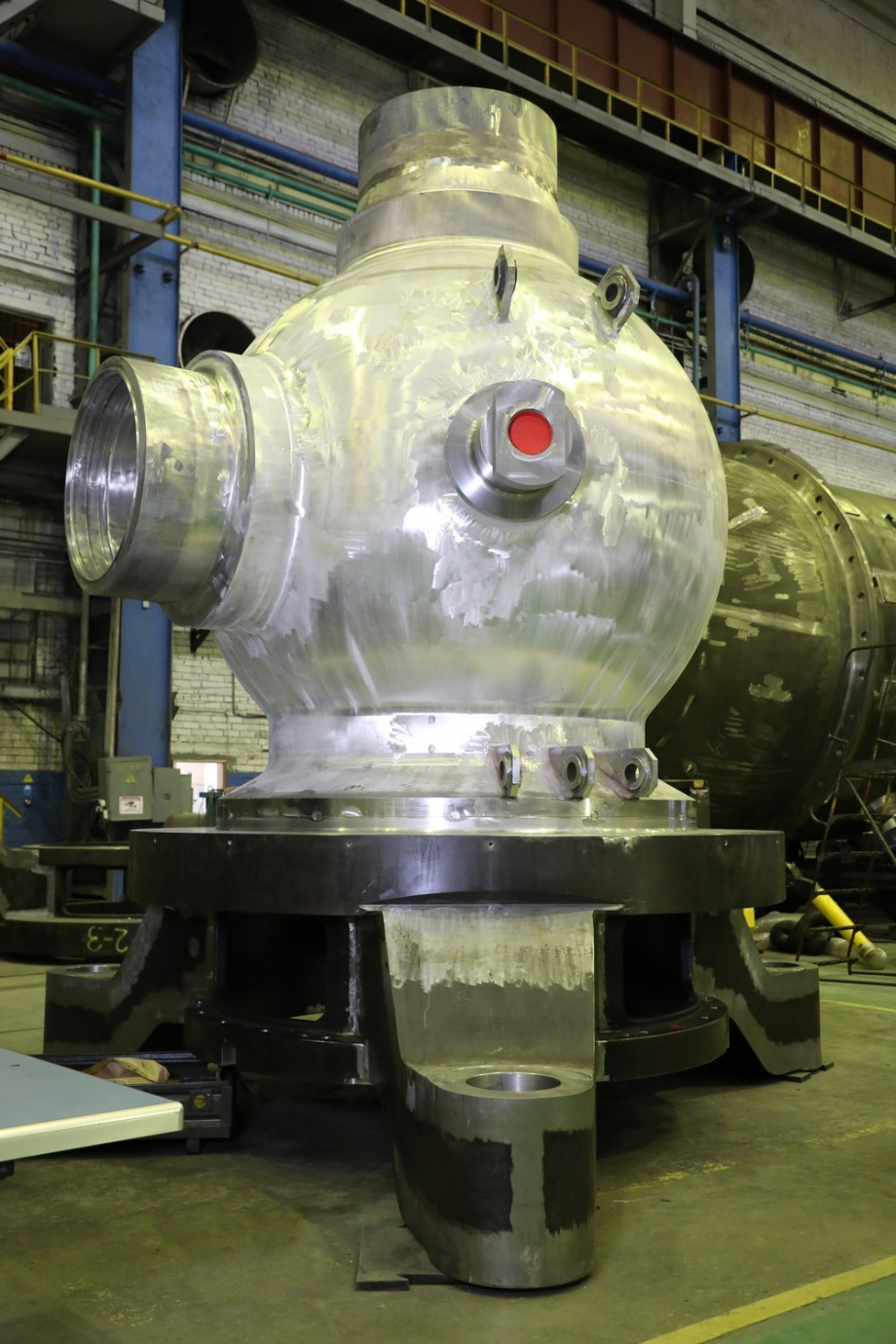

Petrozavodsk Branch of JSC “AEM-Technologies” (a part of machine-building division of Rosatom State Corporation – Atomenergomash and a Karelian regional branch of the Russian Engineering Union) has brought off the check fit-up of the first housing for the reactor coolant pump set (RCPS) intended for Akkuyu NPP, power unit No. 2 being under construction in Turkey.

During the fit-up there has been checked assemblability of the RCPS spherical housing with the spacer being the suspension component as well as with the inner cone. Upon that, there have been met all the requirements of the design documentation related to geometrical dimensions of joints and forces of fasteners tightening. The representatives of the authorized organization JSC “VO “Safety” and the Turkish Atomic Energy Authority (TAEK) have rated the results of the performed operation as favourable ones.

The check fit-up is one of the final inspection operations during manufacture of the RCPS bodies. After that the items are to be submitted for painting and preservation.

The RCPS body is an item of the first safety class. At a nuclear power plant, the reactor coolant pump set provides coolant circulation in the primary circuit and operates under pressure of about 16 MPa and at temperature of about 300 °С. Weight of one body is more than 31 t with a height of 3.5 m and a width of more than 3 m. Weight of the item assembled with the spacer amounts up to 48 t. The reactor plant equipment of one power unit includes four RCP sets.

Akkuyu NPP is the first nuclear-industry-related project in the world being implemented pursuant to BOO (“build-own-operate”) approach. The project Akkuyu NPP includes four power units equipped with Russian III+ generation VVER-reactors with increased safety and advanced technical and economic characteristics. Power of each NPP unit will be 1200 MW. Principal stages of manufacture are supervised by the Nuclear Regulatory Agency of the Republic of Turkey (NDK).