|

Ensuring industrial safety and environmental integrity are priority tasks for AEM. As a large holding in the power engineering industry in Russia, AEM is aware of the nature and the impact of its activities and considers it its duty to maintain safe working conditions for employees and partners, as well as to minimize the impact on the environment. Nuclear power is included in the list of "green" activities of the Russian Taxonomy due to the fact that there are no CO2 emissions during the operation of nuclear power plants. This fact places nuclear energy on a par with renewable sources of generation. Not only the level of safety of equipment, production and operation of nuclear power plants is growing, the “atom” is gradually entering a closed cycle in order to become a “renewable” source of energy. Nuclear power generation is one of the main sources of low-carbon energy and has a significant environmental impact. The operation of all Russian-designed NPPs in the world prevents emissions of about 210 million tons of CO2 per year, including 107 million tons of CO2 (estimated based on the global structure of electricity generation by source for 2018) in the Russian Federation. The nuclear power plant has been providing stable generation of low-carbon electricity for 60 years. Also, the construction and operation of a nuclear power plant ensures the formation of an appropriate infrastructure, fundamental and applied science, and a national personnel training system are developing. To minimize the impact on the environment, enterprises of AEM are constantly improving their equipment, as well as monitoring and diagnostic systems for reactor facilities, thereby extending the life of nuclear power plants.

|

ENVIRONMENTAL PROTECTION |

|||

|

Responsible attitude to the environment, increasing the efficiency of production activities, wise use of natural resources and minimizing the impact on the environment of the regions of presence are the Division's social responsibility and part of the corporate culture. AEM recognizes the importance of involving its employees in the climate agenda. Every year, AEM enterprises hold volunteer tree planting events, garbage collection campaigns in the territories of presence. Lectures are held aimed at developing awareness and understanding of employees' responsibility for the preservation of the environment.

|

CLIMATE IMPACT MANAGEMENT |

|||

|

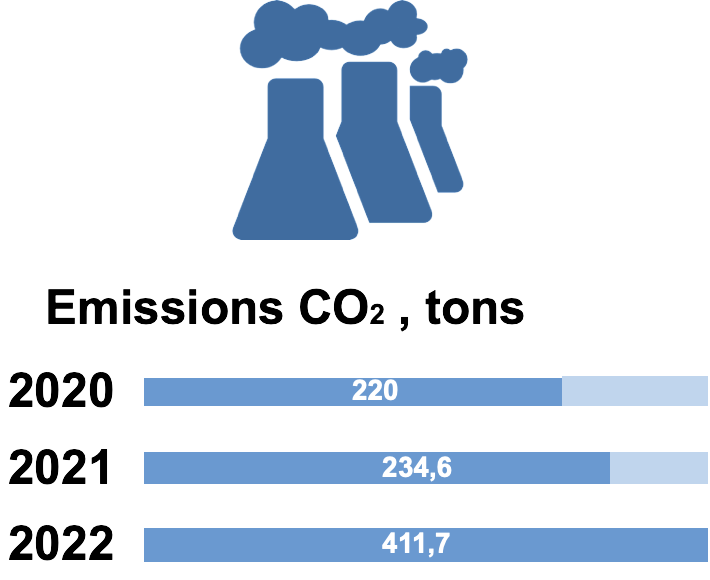

In accordance with the legislation of the Russian Federation, the enterprises of the Division develop draft standards for waste generation and limits for their disposal, as well as draft maximum permissible emissions of pollutants into the atmosphere. Enterprises operate within the framework of regulatory documents. Within the framework of measures to reduce CO2 on the territories of enterprises, the following measures are carried out:

|

WASTE MANAGEMENT |

|

|

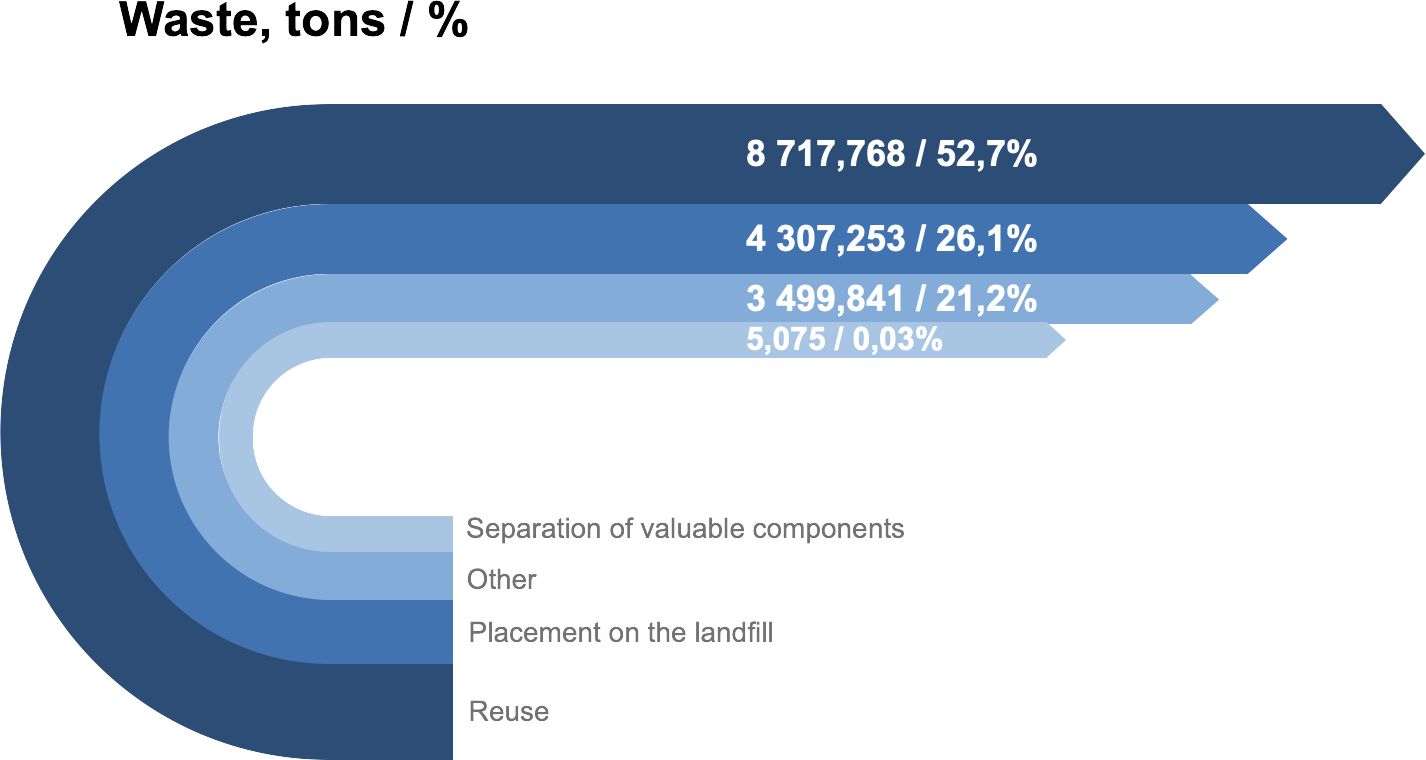

Adhering to the global trend of adhering to the principles of a socially responsible company, AEM enterprises carry out separate collection of production waste, including at the level of local initiatives. For example, ZiO-Podolsk JSC and the branch of AEM-technologies JSC, Atommash in the city of Volgodonsk introduced separate waste collection. In addition, the Division's specialists carry out volunteer campaigns for the separate collection of waste: environmental and charitable projects have been launched to collect batteries and bottle caps with subsequent delivery to a collection point, where they are disposed of without harm to the environment. The main method of waste recycling at the enterprises of the Division is reuse.

|

WASTE MANAGEMENT |

|||

|

|

Atomenergomash JSC designs, develops and manufactures key equipment for medium and high power thermal power facilities. As part of the construction of environmentally friendly waste-to-energy plants (WEP), Atomenergomash JSC ensures the production and complete delivery of equipment for the boiler and turbine islands. Waste-to-energy plants are the best alternative to landfill, as they efficiently convert non-recyclable waste into energy, thereby reducing the share of municipal solid waste disposal. Such a comprehensive waste management solution ensures efficient resource conservation and sustainable development of regional ecosystems. ENERGY EFFICIENCYFor more than 10 years, the Division has been working to improve energy efficiency based on the principles of rational use of resources, meeting the requirements of Russian environmental legislation and the company's voluntary obligations. Atomenergomash JSC pays special attention to ensuring environmental safety in the territories where enterprises are located, rational use of natural resources and energy conservation. The implementation of automated energy metering systems and methodology for improving energy efficiency is underway. In particular, the enterprises are taking measures to reduce mercury-containing waste of hazard class I by replacing fluorescent lamps with energy-saving LED ones.

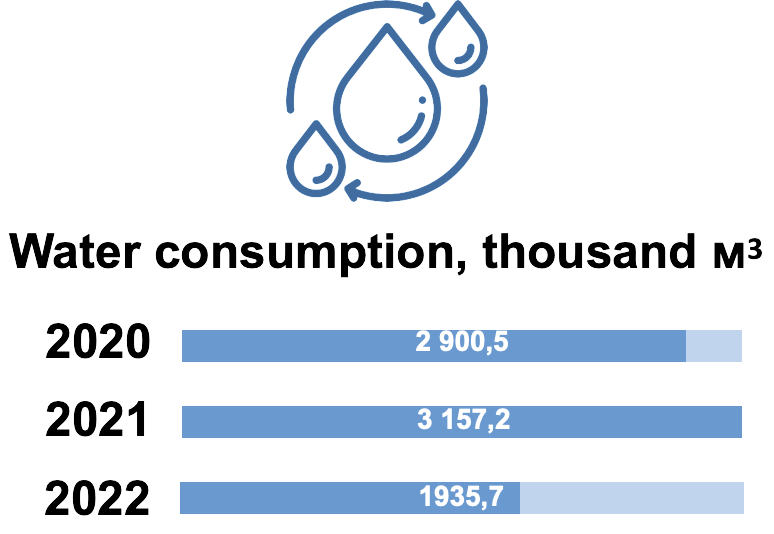

WATER CONSUMPTIONThe quality of water and its availability largely determine the quality of life of millions of people, affect the development of the economy and biodiversity. Activities of Atomenergomash JSC involve the use of a significant amount of water resources. Water resources support the economic activities of the division's enterprises, and are also used in technological processes (cooling/heating systems, when checking the tightness of products, are part of process fluids). The company strives to efficiently use water resources, reducing specific water consumption, reusing water and purifying waste water. Compared to 2019, water consumption has decreased.

|

WATER TREATMENT AND WATER PURIFICATION |

|||

|

Atomenergomash JSC is a developer and a complete supplier of a salt-containing effluent evaporation unit (SEEU). The equipment is designed for the processing of contaminated saline effluents from technological production. The use of evaporation plants makes it possible to effectively clean wastewater from contamination and obtain demineralized water of the required quality.

The water used in production (mainly for cooling equipment and products) is purified and used in the technological process many times. Thus, there is a significant saving in the consumption of clean river water and there is no cooling water runoff into reservoirs. For the purification of industrial and domestic water at the enterprise, modern technologies are used, including a salt-containing effluent evaporation unit. |